Automatic Tabletop Hand Sanitizer Bottle Liquid Filling Capping Labeling Machine line

Product Description

Automatic Tabletop Hand Sanitizer Bottle Liquid Filling Capping Labeling machine line

Product Description

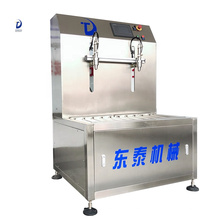

The hand sanitizer Filling machine, as its name implies, is a filling machine used to fill paste, viscous liquid, and viscous fluid. The hand sanitizer filling machine generally uses compressed air as the power, which is easy to operate and simple in structure.

Hand sanitizer filling machine is our company's filling and sealing equipment series, which is suitable for filling various round, special-shaped bottles and small bottles. Hand sanitizer filling machine It is mainly suitable for filling various injections, disinfectants, oral liquids and syrups, alcohol and various medical liquids. It is widely used in the fields of food, pharmacy, chemical industry and scientific research. .

Configuration

name | Liquid filling machine | ||||||

Power supply | 220 / 110V 50/60 Hz | ||||||

Filling range | 5-60ml | ||||||

Power | 10 watts | ||||||

Pressure | 0.4-0.6 MPa | ||||||

Filling speed | 30-50 bottles/min | ||||||

Filling accuracy | ≤±1% | ||||||

Net weight | 37kg | ||||||

Filling volume | 3-1000ml(220V)3-500ml(110V)since the power of 110v mechine is not lange, so we recommend 3-500ml for each nozzle | ||||||

easy to operate

Liquid filling machine It is easy to operate, and the pneumatic parts adopt pneumatic components from Germany FESTO and Taiwan AirTac.

The structure is simpler and more reasonable, the accuracy is high, and the operation is easier.

PLC and color touch screen control

Imported programmable controller PLC and color touch screen control, the Liquid filling machine control system is more accurate and reliable. More than 20 recipe parameters can be stored. When customers fill materials with different specifications and different densities, they can preset and store parameters, and switch with one key.

No drip filling head

The filling volume and filling speed can be adjusted arbitrarily. The filling head adopts anti-drawing and lifting filling device.Liquid filling machine The filling head and cylinder of the Liquid filling machine adopt a split mechanism, and the accessories use standard parts, which are easy to replace and maintain.

316 stainless steel

The Liquid filling machine material contact parts are made of 316L stainless steel, which meets GMP requirements.

The filling valve is controlled by a solenoid valve, and the filling accuracy is higher.

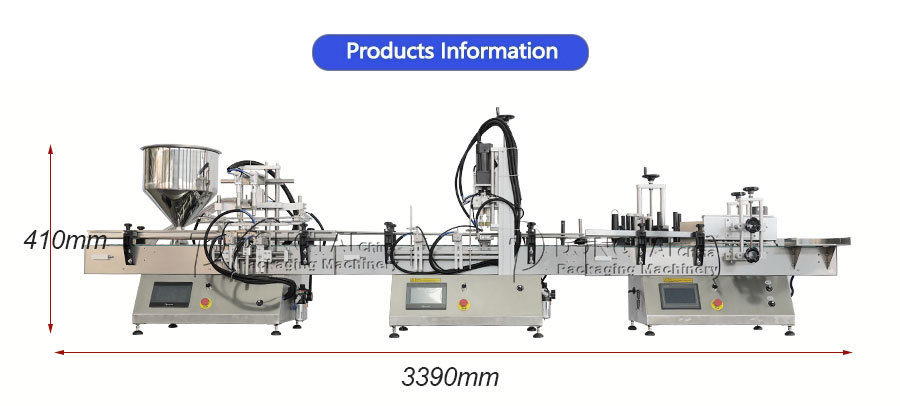

Working Voltage | AC220V/110V 50- 60HZ | ||||||

Bottle Height | 60-270mm | ||||||

Bottle Caps Diameter | 18 -70mm | ||||||

Working Speed | 20- 40 bottles/minute(depending on bottle and cps) | ||||||

Working Pressure | 0.4-0.6 MPa | ||||||

Machine Size | 1120* 580* 1110mm | ||||||

Conveyor Length | 1110mm | ||||||

Net Weight | 65kg | ||||||

Package Weight | 97.5kg | ||||||

Package Size | 1160*610*1140mm | ||||||

Size Of Air Compressor Connector | OD 8mm | ||||||

Voltage | 110V-60HZ / 220V-50HZ | ||||||

Working speed | 20-50ottles/min | ||||||

Suitable labeling size | 15-140mm (W) X 25 300mm (L) | ||||||

Roll inside diameter | φ76mm | ||||||

Roll outside diameter | φ350mm | ||||||

Suitable bottle diameter | ≤100mm | ||||||

Net weight | 95.5kg | ||||||

Package Size | 1270*530*820mm | ||||||

Gross weight | 125kg | ||||||

Size of air compressor connector | OD 8mm | ||||||

Recommended Products

Company Profile

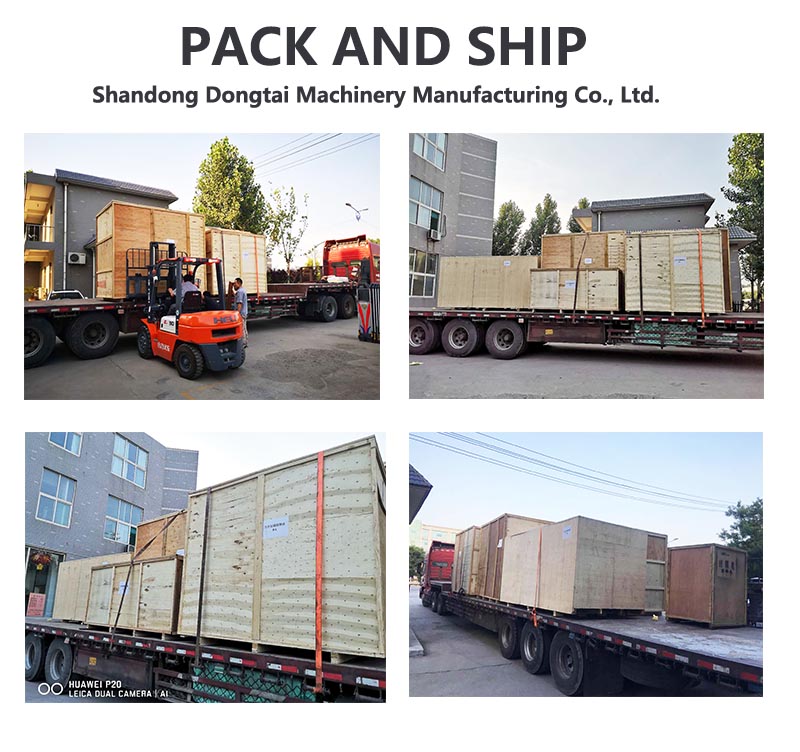

Shandong Dongtai Machinery Manufacturing Co., Ltd. is located at No. 3843 Airport Road, Lingang Street, High-tech Zone, Jinan City, Shandong Province. The factory covers an area of 100 acres. It has obtained ISO9001 quality system certification, ISO14001 environmental management system certification, CE certification and multiple invention patents.With an annual output of nearly 100 production lines. Its outstanding performance and perfect after-sales service system have won unanimous praise from users.

CE Certification

All of our filling machine is made of superior spare parts,the processing line assembled strictly according to ISO9001 regulation,so our equipment fully in accordance with the GMP&ISO standard production and passed CE certification.Packing and shipping

Conventional raw material packaging 1. The surface is treated with rust prevention, 2. Inner plastic waterproof packaging, 3. Fix the outer layer of the lubricating oil filling machine with thick wood or steel frame, and then pack it with synthetic board. Combined container transportation, or separate container transportation.

FAQ

What is your manufacturing time?

7 days!!!!

For emergent needs of special parts, the process could be shortened.

What is the warranty and how is the after-sale service?

One-year warranty!!!!

Technicians will guide you to install, test machines, and provide free training to your staff in terms of operating and maintaining the machines. Operating manuals will also be sent with machine or by email.

Can you arrange technicians for overseas debugging?

Yes!!!!

we can provide services as needed exclude visa fees, round-trip air tickets, and accommodation. We can also arrange your technicians to study in our factory before shipment.

Is the machine available with 240V/220V/110V?

Definitely!!!!

We provide solutions and converter to different power sources and different plug bases for customers from all over the world.

Do you have any certification?

YES!!!!

We are CE and ISO9001 certified company.

Product Categories : Semi-auto filling machine > Liquid(oil)filling machine

Other Products

Hot Products

Dual-Purpose Mosquito Liquid and Refill Electric Mosquito Liquid with ChargeKonnor Electric Mosquito Liquid VaporizerKonnor Electric Mosquito Mat HeaterRenew Fabric Stiffing Cold Water Speed Powder StarchHot Sale Good Fast Clean Starch Spray Cloth Cleaning Spray140mm Africa No 1 Quality Black Mosquito Coil360ml Aerosol Car Air FreshenerDual Purpose Heating Device for Mosquito Liquid and MatMosquito Mat VaporizerBlack Mosquito Coil (with tiny smoke)Mosquitoes Liquid (Prallethrin Active Ingredients)Mosquito Tablets with 15mats*2/BoxMosquito Paster with Cartoon DesignSongpush Room Spray Various FragranceWater Based Insecticide SprayTox Zappo Knock Down Faster Insect Killer Spray