Automatic brand cooking oil bottling machine from China

Product Description

The filling part of the machine realizes fast filling and slow filling through double cylinder. After the initial filling of the cylinder, the double cylinder is converted to the stroke 1 and quickly converted to the stroke 2 for quick filling. After filling to the fast filling set, the submergence cylinder rises to the barrel, and the double cylinder is converted to the stroke 1 to continue the slow filling until the overall filling amount is set.

1. Automatic edible/cooking/vegetable oil filling machine---Appllication

1). the advantage of flow meter way: The adjustment in dosage is convenience and quick, the volume only need to be set on the touch screen directly, considered that the vegetable oil is different in density in the different temperature, resulting in the volume setting different, we have added an automatic temperature-compensated system.

2). the accuracy of filling: instead of the traditional computing type of flow meter -- through pulse generator, now promoted by our company, adopting rotary encoder is more accurate.

3).the speed of filling: instead of the traditional power delivery -- pressure artesian flow, our machine adopting frequency converter to adjust the speed of filling, the efficiency highly raised. The speed can be arbitrarily adjusted on panel. the adjustment of filling accuracy, promoted by our company, the weight of filling can be set on the touch screen.

4).It will not affected by the season, In summer and winter the oil all can be fill easily, not restricted by the viscosity of oil products, such as gear oil can also be easily filled. The more viscous material is, the more obvious the advantage of flowmeter filling method is.

5).The operation interface is simple, easy to learn and maintain, low requirements for field operators, use of startup and formula adjustment and one key solution.

6).no wearing parts in the production process, mechanical transmission, The total cost in use is lower.

2. Flow meter principle

The principle of the elliptic gear flowmeter is to measure the rotation of the elliptic gear by the pressure head of the measured medium. The greater the viscosity of the medium, the smaller the leakage from the gear and the space gap, the greater the viscosity of the medium, the smaller the leakage error and the more favorable for the measurement. The elliptical gear flowmeter has high accuracy and is suitable for the measurement of the flow rate in the medium with high viscosity, especially for the filling of different labels and different viscosity.

3. Automatic edible/cooking/vegetable oil filling machine---Technical parameter

Flowmeter way:

1. 1-20L Large filling volume range

2. Controled by encoder, high accuracy

3. one head one flowmeter, Independent control

Stainless steel Centrifugal pump

1, Flow: 6m³/h, lift: 13M, revolution: 2900 r/min

2, High in speed, low nosie

3, CE certification

Patent techology filling nozzle

Touch-screen panel

1. Easy operation, full english panel, other language could customized

2, Simple and Direct, save parameter

3, More Intelligent, which can input the language as customer requirements

The whole pipeline can be made up of multiple PLC systems. Each system can be controlled independently and interlocked. It has the functions of self inspection of the system, fault alarm and display of motion state, precision, speed, adjustment and cumulative production. All the systems are equipped with man-machine interface, and all the parameters can be operated on the man-machine interface. Provide detailed pipeline control process flow chart and logic diagram. And the system can store multiple specifications, one key switch, no need for cumbersome settings.

The liquid level control and adjustment system of filling tank can be completed by product pump and self control function. The liquid level in the filling tank is displayed in real time, and the intake valve is automatically controlled according to the level of the fuel tank, and it is alarms at high or low liquid level. The filling tank should be equipped with a cleaning spray system, which consists of a spray tube and a pneumatic ball valve. When the material needs to be switched, the oil of the tank is cleaned, the cleaning ball valve is automatically opened and the cleaning oil is sprinkled on the tank wall. It is possible to manually and automatically clean pipes and filling heads. Liquid level automatic control and high and low oil level alarm and liquid level display.

Inorder to ensure product quality, all suppliers of raw materials, electrical components, and industrial automation that strictly control all aspects of circulation are from well-known brands at home and abroad. They must be strictly inspected by quality inspectors before entering the warehouse. Use, product production is completed, from the assembly plant into the commissioning workshop, after a number of rounds of precision and speed test, after commissioning can be allowed to leave the factory.

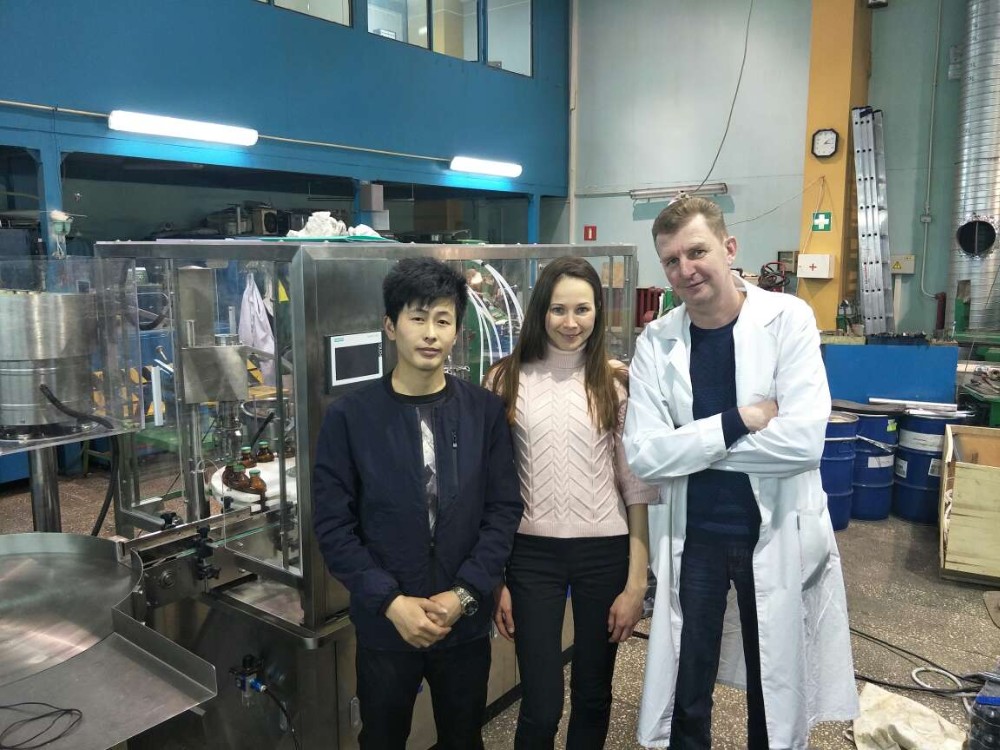

1. Technical support online service provided.

2. Technical files service provided.

3. On-site training service provided.

4. Spare parts replacement and repair service provided.

1. Cover by PVC film + fumigated wooden case;

2. Wooden case suitable for long distance ocean shipping.

Jinan Dongtai Machinery Manufacturing Co., Ltd. was established in 2008 and is located in Lingang Economic Development Zone, Jinan, China. The company is committed to the design, manufacture and sales of packaging machinery and equipment. It is a high-tech enterprise specializing in the research and development, production, sales and service of automated packaging machinery equipment. The company has professional technicians, engineers and sales and after-sales service personnel, forming a team of high quality, young, highly innovative spirit.

Factory

Workshop

Work environment

Team

Product Categories : ALL products > Filling machine

Premium Related Products