dropper bottle automatic tube fragrance pneumatic bottle 10 litre liquid filling machine

Product Description

dropper bottle automatic tube fragrance pneumatic bottle 10 litre liquid Filling machine

Product Description

It is widely used in the fields of food, pharmacy, chemical industry and scientific research. It is suitable for filling and capping (rolling) of various round, special-shaped bottles and vials. The dropper bottle filling machine is mainly suitable for various injections and disinfectants. , Oral liquid and syrup, wine, essential oil and various medical liquid filling,plugging and locking (rolling) caps.

product name | liquid filling machine |

Applied Bottle | 20-500 ml |

Productive Capacity | 10-50pcs/min 4filling nozzles 50-60pcs/min 6 filling nozzles 60-80pcs/min 8 filling nozzles 80-100pcs/min 10 fillling nozzles 100-120pcs/min 12 filling nozzles |

Filling Tolerance | 0-2% |

Qualified Stoppering | ≥99% |

Qualified cap putting | ≥99% |

Qualified capping | ≥99% |

Power Supply | 380V ,50HZ |

Dimension | 2500(L)×1000(W)×1700(H)mm |

Net Weight | 600KG |

Power | 1.5KW |

Details Images

bottle unscrambler machine

The automatic tube filling machine disc (rotary)type unscramble bottle machine place the empty bottle orderly and then convey to the belt.

Filling station

With anti-drop device, high precision, the structure of the fragrance filling machine can be customized according to the filling volume and material.

Inner plug vibrator

Equipped with anti-drop device and high precision, the structure of the liquid filling machine 10ml can be customized according to the filling volume and material.

Inner plug station

Inner plug manipulator inhale the plug and press into the bottle accurately.

Cap sorting vibrator

The pneumatic liquid filling machine sorting cover vibrating plate fixes the cover, feeds the slide, and then slides into the hanging cover.

Hang cover station

When the 10 litre liquid filling machine ps hangs the lid, the bottle hangs the lid.

Press plug and Lock cover station

After hang the covers, Press the plug down to the bottom by press plug hammer ,lock cover machine press the cap and bottle body into one though claw knives.The sealing structure can customized the different kinds of covers, such aluminium covers (common press cover)pltic covers(common screw cap) etc.

The liquid filling machine bottle is our company's traditional series of filling and capping equipment, which is suitable for filling and capping all kinds of round, special-shaped bottles and small bottles. It is mainly suitable for filling various injections, disinfectants, oral liquids and syrups, wine, essential oils and various medical liquids.

The dropper bottle filling machine is suitable for filling various specifications of liquid filling. Servo piston metering ensures that the filling accuracy is 1‰. The filling speed is increased by 20%-35%. The operation is simple, the labor cost is saved, and the production efficiency is high.

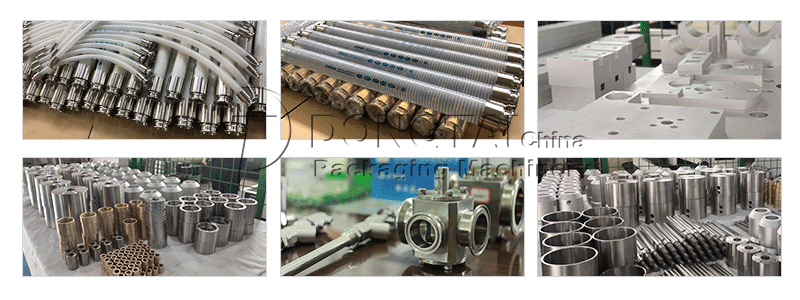

The whole machine is stable and reliable. The parts and auxiliary equipment of the automatic tube filling machine are directly provided by the brand agent. The brand guarantees quality. Imported Airtac cylinders are sturdy and durable. Other seals and other accessories use standard parts that are easy to replace and maintain.

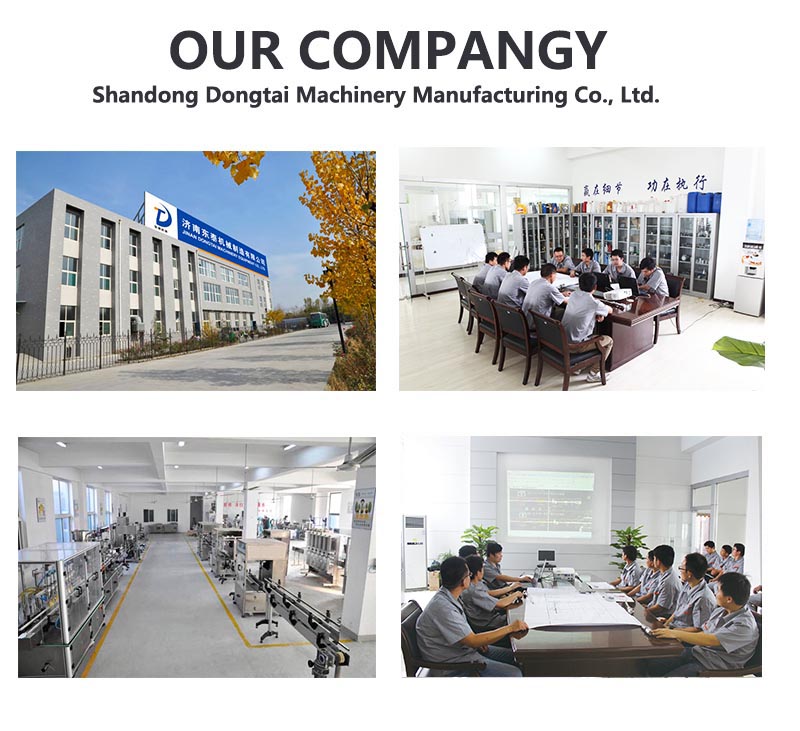

Company Profile

Shandong Dongtai Machinery Manufacturing Co., Ltd. is located at No. 3843 Airport Road, Lingang Street, High-tech Zone, Jinan City, Shandong Province. It has five companies. Shandong Dongtai Machinery Manufacturing Co., Ltd. is a manufacturer of chemical intelligent equipment. The factory covers an area of 100 acres. With a construction area of 10,000 square meters and more than 150 employees, it has obtained ISO9001 quality system certification, ISO14001 environmental management system certification, CE certification and a number of invention patents. For more than ten years, after the hard work of Dongtai people, Shandong Dongtai Machinery Manufacturing Co., Ltd. has continued to innovate and develop and keep pace with the times. It has provided many companies with generations of advanced intelligent packaging equipment and created industrial intelligent chemicals for customers Factory; provide customers with automated three-dimensional warehouses;Shandong Dongtai Machinery Manufacturing Co., Ltd. is a high-tech enterprise, a member enterprise of the World Trade Center, and a member enterprise of the national and provincial industrial associations. So far, its excellent performance and perfect after-sales service system have won unanimous praise from users.

We provide engineers with one-stop service of on-site measurement, design drawings, installation and training. Tailored to your special filling requirements. We provide one-stop service for engineers, including on-site measurement, design drawings, installation and training. Tailored to your special filling requirements.

Exhibition & customers

Our machines are located in many countries around the world, and we have a good reputation and end user satisfaction wherever our machines are located.

Dongtai has established a strategic alliance business relationship with partners all over the world in response to international demand. Its products are sold well in Europe, America, Southeast Asia and other countries and regions, and are received at home and abroad with "excellent quality, excellent service and reasonable price". Customers' favor.

Packing and shipping

Conventional raw material packaging 1. The surface is treated with rust prevention, 2. Inner plastic waterproof packaging, 3. Fix the outer layer with thick wood or steel frame, and then pack it with synthetic board. Combined container transportation, or separate container transportation. transport: 1. The standard plywood box body has better compressive strength and bearing quality. 2. The board area is small, the soil structure is good, and the leakage and water resistance are good. 3. When imported, the plywood box is free of fumigation, and the operation is simple.

company certification

All of our filling machine is made of superior spare parts,the processing line assembled strictly according to ISO9001 regulation,so our equipment fully in accordance with the GMP&ISO standard production and passed CE certification.

FAQ

1: When was Dongtai Machinery established? Answer: It started in 2008 and now has about 12 years of experience in the packaging industry. 2: What is your delivery time? Answer: It usually takes 30 days to produce, but if there are spare parts in an emergency, it can be completed within 15 days. 3: What is the warranty? Answer: The warranty period is 1 year and does not include easily damaged spare parts, such as heaters, belts, etc. 4: How do you recommend a suitable filling machine to me? Answer: You need to provide us with detailed filling requirements, including packaging products, bottle size, packaging weight, bottle type, etc. 5: Can we arrange technicians for overseas debugging? Answer: Yes, we can provide services as needed, but the fees you need to pay include visa fees, round-trip air tickets, accommodation and labor fees. We also accept you to arrange technicians to study in our factory before shipment.

Product Categories : ALL products > Filling and sealing/capping machine

Premium Related Products

Other Products

Hot Products

Dual-Purpose Mosquito Liquid and Refill Electric Mosquito Liquid with ChargeKonnor Electric Mosquito Liquid VaporizerKonnor Electric Mosquito Mat HeaterRenew Fabric Stiffing Cold Water Speed Powder StarchHot Sale Good Fast Clean Starch Spray Cloth Cleaning Spray140mm Africa No 1 Quality Black Mosquito Coil360ml Aerosol Car Air FreshenerDual Purpose Heating Device for Mosquito Liquid and MatMosquito Mat VaporizerBlack Mosquito Coil (with tiny smoke)Mosquitoes Liquid (Prallethrin Active Ingredients)Mosquito Tablets with 15mats*2/BoxMosquito Paster with Cartoon DesignSongpush Room Spray Various FragranceWater Based Insecticide SprayTox Zappo Knock Down Faster Insect Killer Spray